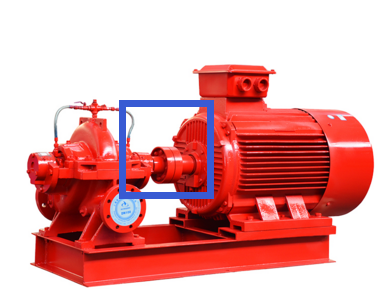

Mechanical equipment, rust, leakage and other problems, broken, everyone thinks, it must be that the product quality is too bad. It has also been said that the normal fire pump shaft will not break. Actually not, the pump shaft of the fire pump will also break. The reason for this is that in addition to the quality of the product itself, there are others.

5 reasons for break of fire pump shaft

1. The precision of the pump shaft casting is not enough, resulting in the phenomenon that the pump shaft of the fire pump is broken.

2. The fire pump has been in a humid environment for a long time, and corrosion occurs everywhere in the fire pump. The pump shaft of the fire pump is no exception. Or, the liquid pumped by the fire pump for a long time is extremely corrosive and the pump shaft material is not selected for corrosion resistance. The pump shaft material is so as to cause breakage after corrosion.

3. The heat treatment of the fire pump shaft is not in place, causing the pump shaft to break.

4. The pump shaft of some fire pumps needs to be welded. During the welding process, the process is not completed, resulting in fracture at the weld.

5. The hard object is sucked into the pump and the impeller is stuck. However, some small models of the fire pump have a thin pump shaft and will break.

The fire pump pump shaft is used to transmit torque and rotate the impeller to open the operation of the fire pump. If it breaks, it will not only be partially damaged, but will cause the fire pump to be completely inoperable and become a waste mechanical product. In addition, the material and structure of the pump shaft of the fire pump are used to transmit power and rotate at a high speed. In a pump that transports non-corrosive medium such as clean water, it is generally made of 45 steel and is subjected to quenching and tempering treatment. In a pump that transports a weakly corrosive medium such as a salt solution, the pump shaft material is treated with 40Cr and quenched and tempered. In the anti-corrosion pump, that is, the pump for transporting strong corrosive medium such as acid or alkali, the pump shaft material is generally stainless steel such as lCr18N19lCr18Ni9Ti.