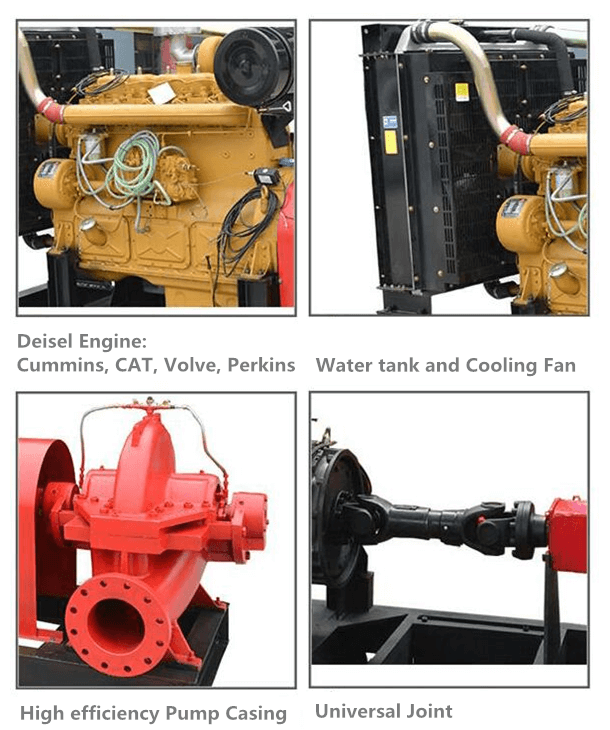

At the moment when fire safety goes deep into people's minds, diesel fire pumps gradually replace ordinary fire pumps, especially in manufacturing companies, large-flow water supply systems, high-efficiency performance, and stable operation methods. These are the most reliable fire safety protection experts for modern enterprises. However, the more expensive and high-tech products are, the more they need attention.

Fire safety support expert - diesel engine fire pump also needs care

Diesel engine fire pumps, like ordinary fire pumps, require regular cleaning and maintenance, especially preventive maintenance:

First, The user should keep the engine room where the diesel engine fire pump is located clean and tidy so as to avoid adverse operations caused by environmental pollution and ensure that the external parts of the unit and its supporting equipment are flexible and reliable;

Second, pay attention to regular inspections, check the scope of inspection includes checking whether the pump group's institutions are in good condition, whether the fuel tank, engine oil sump, heat exchange, header and foam fluid capacity are sufficient, the engine oil circuit, the circuit is normal and reliable. In addition, it is also necessary to check the starting performance of the engine. Every week must be after idling. Pumping runs for a number of hours. Thereby ensuring the reliability of the entire control system.

Third, ensure that the joint surface between the pump and the pipeline should ensure good air tightness. In particular, the inlet piping must be tightly sealed and there should be no possibility of air entrapment.

In addition, to prevent damage to the pump, the piping must be cleaned before the pump tubing is connected. In and out of the water pipe should be provided with a separate support, shall not be supported by the unit body. The suction line of the pump should be short and straight. The pipe diameter should be greater than or equal to the pipe diameter of the suction inlet of the pump, and the elbow radius of the suction pipe of the pump should be made as large as possible.