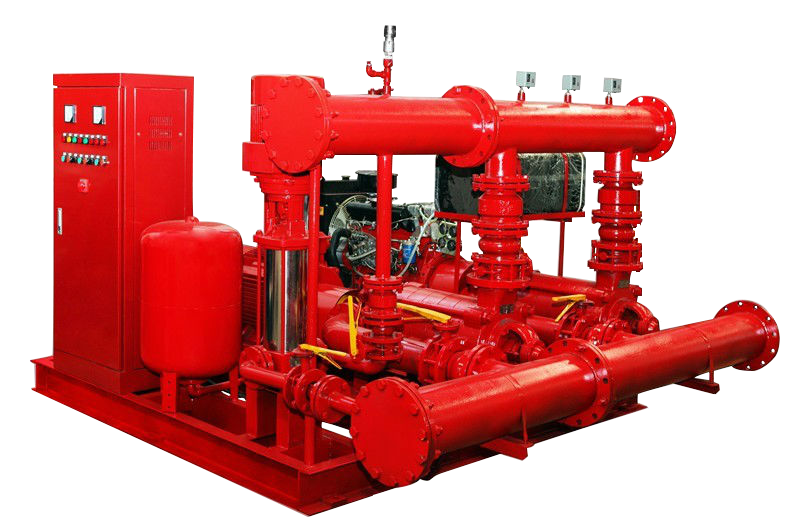

High temperature or low temperature: For transporting high and low temperature medium

chemical pump, materials used both in situ temperature, normal room temperature, or in the transmission medium temperature must have sufficient strength and stability. Another important thing is that all parts of the pump are used to withstand thermal shock and therefore different thermal expansion and the risk of cold brittleness generated.

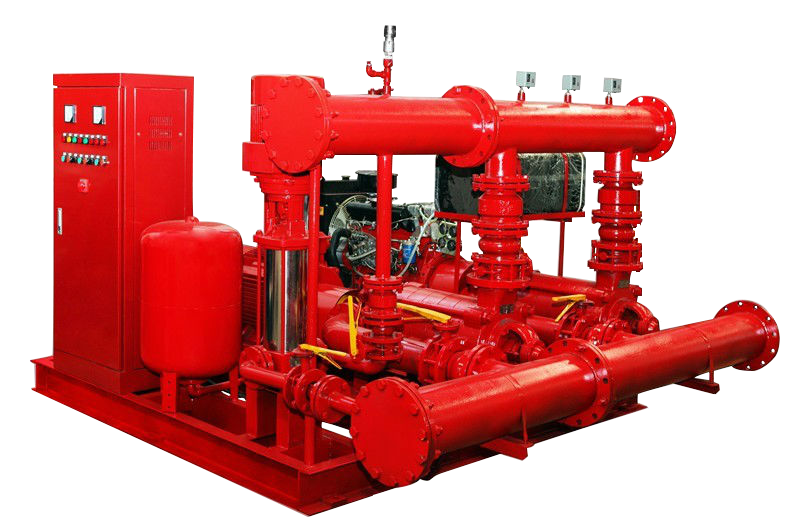

In the petrochemical production process, the fire pump not only plays a role in transporting the material, but also to provide the necessary amount of material to the system to achieve the material balance of chemical reactions, pressure to meet the desired chemical reaction. If the scale of production does not change occurs, the nano pump flow and head have relatively stable. If affected by certain factors, flow rate and outlet pressure of the water pump should be followed by changes in the production fluctuations of the time, and has high efficiency.

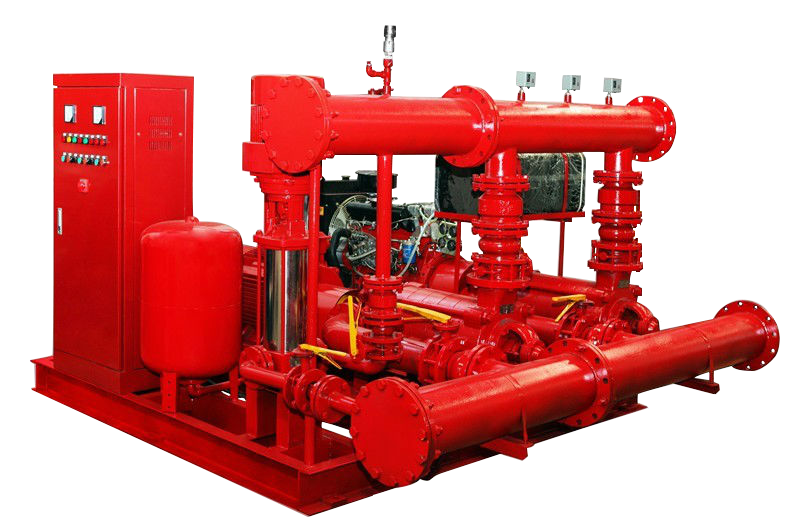

Corrosion-resistant: Chemical pumped media, including raw materials, intermediate products, and other liquids, most are corrosive. Pump improper material selection,during operation of the pump, the component will fail due to corrosion by the medium, it does not work.

Suspended solid particles will flow conveying speed of chemical contained in the pump caused by wear and tear. Once the chemical pumps worn, damaged, it will exacerbate medium pump corrosion. Since the majority of corrosion resistance of metals and alloys is built on the surface of the passivation film, so if passivation film for wear, nano-metal will be activated in the next state, the situation will be exacerbated by corrosion.

Reliable operation: Reliability chemical pumps run mainly includes two aspects: First, long-term operation without failure. Second, the smooth running of various parameters.

Reliable operation of petrochemical production is crucial, If the pump fails often, not only result in frequent shutdowns, affecting the economic benefits, and there is cause petrochemical production systems Occurrence accidents.

Fire fighting pump speed fluctuations will be flow and pump outlet pressure and other parameters to fluctuate, leading petrochemical production can not function properly, the chemical reaction will be affected, the material can not be balanced in wasteful, it is also the presence of lower-quality product or scrapped possible.

No leakage or less leakage: Liquid medium chemical pumps have delivered most explosive, flammable, toxic and other characteristics, and some media even contain radioactive elements. Pump once these media leaks into the atmosphere, it is likely to cause a fire, health or environmental harm to the human body. In addition, the prices of some of the more expensive media, leaks can cause great economic losses. Capable of delivering the critical state of the liquid.