Multi-stage fire pump shaft means mounted on a string more than two pump impellers, Pump impeller is the number of stages. Its structure is more complex than single-stage pump. The front and rear wheel cover asymmetric structure, under the action of the impeller outlet pressure, force acting on the rear cover is greater than the force applied to the front cover. This is called axial force. According to the axial force balanced way points, it can be divided into two categories categories:

First, a balanced structure of the axial force balance multistage pump;

Second, the self-balancing multi-stage pump.

The first category is divided into multi-stage pump balance holes, drum balance, balance disc and drum set joint structure. Balance leak larger than the pore structure, but also for machining and assembly requirements are relatively high. Balancing drum structure for transporting a large number of chemical media, this structure than the larger leak, in line with API610 requirements; Balance disc structure of the pump is mainly used for transporting medium is water (May contain some impurities); Drum set binding structure is generally used for high-efficiency requirements of local, such as power plant boiler feed water and other occasions.

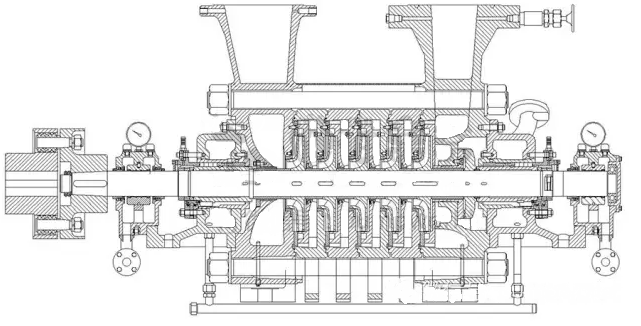

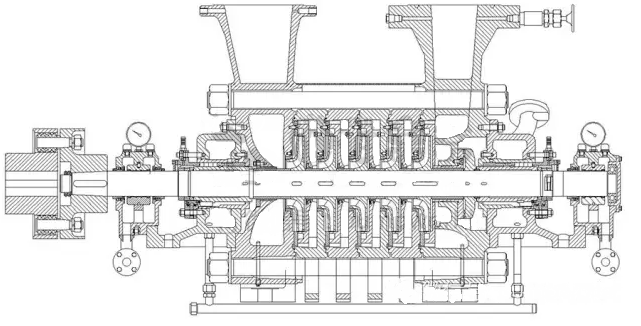

Staged (balance disc structure)

The second type multi-stage pump can be subdivided into volute type with staged, mainly used to transport large amounts of impurities in the wastewater. Since the structure of these two decisions multistage pump volume is relatively large, and the scope of

multi-stage volute pump is relatively narrow, therefore, its very limited quantities.

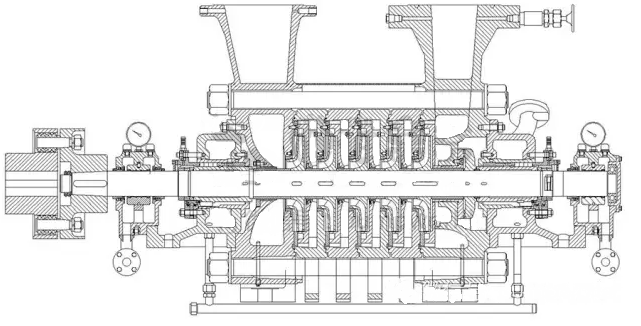

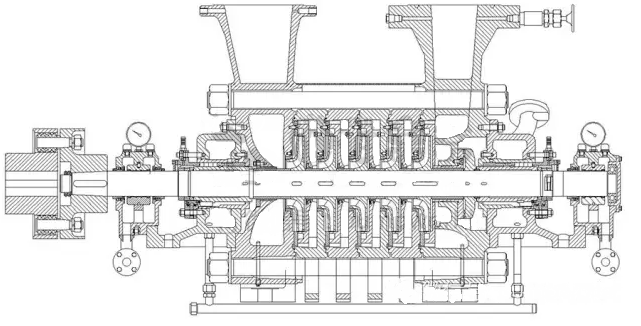

Stage multi-stage pump (self-balancing structure)

advantage:

1, the structure is relatively simple

The first multi-stage pump main parts are mainly water segment, the middle section of the water with the vanes. Simple structure, easy to cast. The second type multi-stage pump flow channel structure is more complex, more difficult to cast.

2, easy maintenance

The first multi-stage pump impeller vanes are the same. Processing, assembling and no need to consider the order of rotation. While the second phase of the formula needs attention multistage pump impeller assembly, guide vane rotation. Maintenance personnel requirements are relatively high. And difficult to troubleshoot if it fails.

3, versatility, high efficiency

The first multi-stage pump main parts are machined finish flow part of the relatively high resistance of the fluid is relatively small, so efficiency is high relative to the casting runner second type multi-stage pump efficiency. And the first class of multi-stage pump impeller, guide vanes, middle interchangeable, generic parts are relatively strong. Runner second type multi-stage pump has symmetrical structure, spare parts need to double, potentially increasing costs.

4, light weight, low cost

The first multi-stage pump with respect to the volume of the second type multi-stage pump to reduce one-half. Especially when the transmission medium for the chemical medium, special high-performance requirements of the material. Therefore, the material cost is relatively high, this time is equivalent to reducing the weight and cost savings.